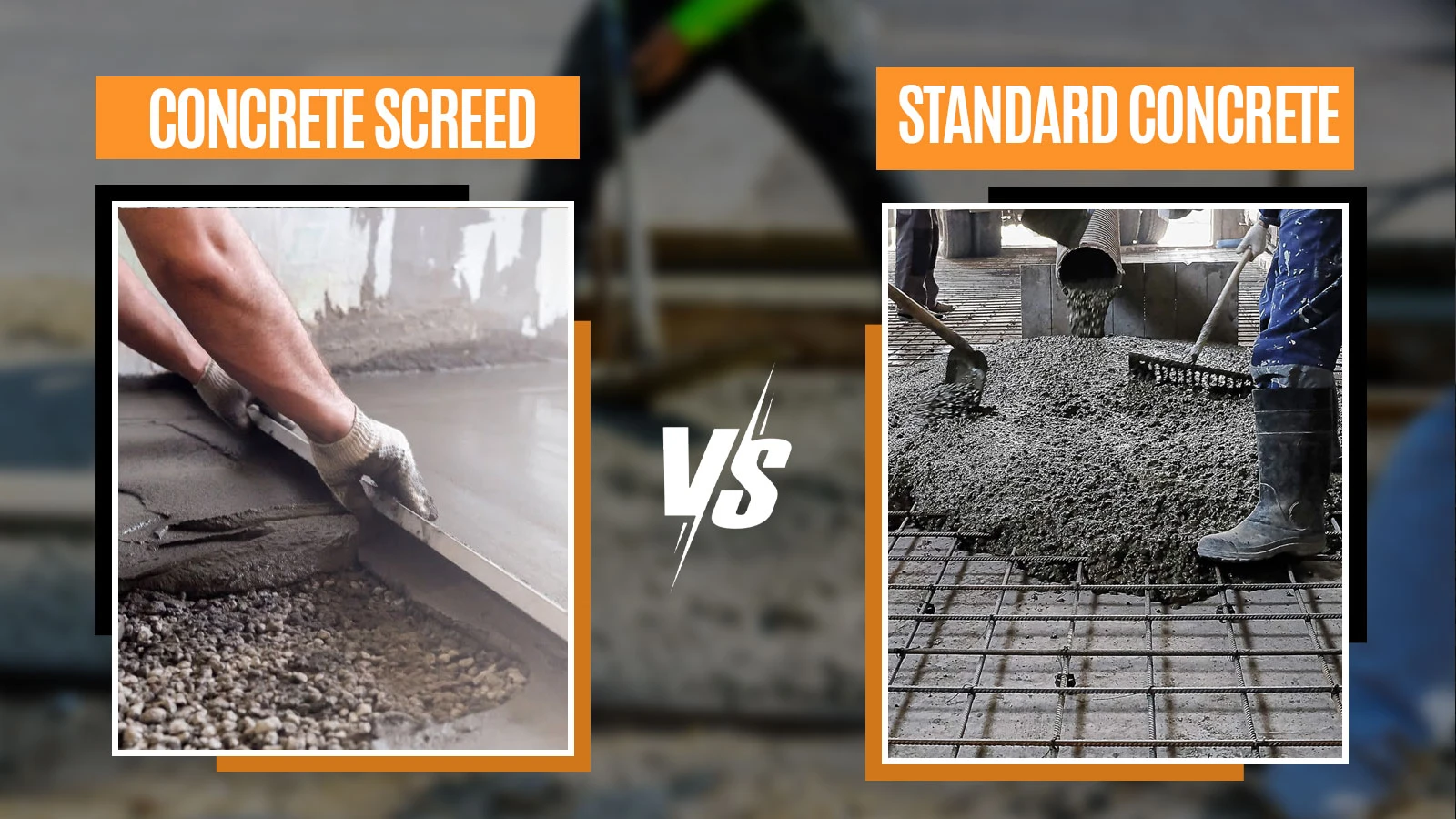

Concrete screed (25-50mm thick) provides smooth finishing surfaces for tiles, wood, and LVT flooring with fine sand aggregate. Standard concrete floors (100mm+ thick) offer structural strength with coarse aggregate for foundations, driveways, and load-bearing applications. Choose screed for smooth finishes and underfloor heating; choose concrete for structural support and heavy-duty use.

Concrete screeding and standard concrete floors serve different but complementary roles in modern construction. Screed acts as a smooth finishing layer over structural concrete, while standard concrete provides the foundational strength for buildings and outdoor surfaces.

Making the wrong choice can result in surface failures, costly repairs, and poor long-term performance. Understanding when to use each material prevents costly mistakes and ensures optimal performance for your specific needs.

You can also get expert guidance and concrete solutions from our specialists at Pro-Mix Concrete, who can help you choose the right material for lasting results. Our experienced team provides comprehensive project consultation and on-site support to ensure your concrete or screed application delivers optimal performance for decades.

[Get In Touch]

What Is Concrete Screed?

Concrete screed is a thin (25–50mm) finishing layer made from cement, fine sand, and water that smooths rough concrete and creates level surfaces for tiles, vinyl, laminate, or wooden flooring.

Composition includes:

- Portland cement is the binding agent

- Fine sand (typically 0-4mm aggregate size)

- Water for hydration and workability

- Optional additives for specific performance characteristics

Main applications cover:

- Finishing layer over structural concrete slabs

- Smooth surface preparation for floor coverings

- Underfloor heating system encasement

- Surface levelling and minor repair work

Types of screed systems:

- Bonded screed: Direct application to concrete substrate

- Unbonded screed: Applied over membrane or damp-proof layer

- Floating screed: Laid over insulation materials

- Underfloor heating screed: Specialised mix for thermal systems

Screed sets faster than concrete, typically within 4-6 hours, making it ideal for quick turnaround projects and renovation work.

What Is a Standard Concrete Floor?

Standard concrete floors are the structural foundation of buildings, made from cement, coarse aggregate, sand, and water. At 100mm or more in thickness, they provide the strength and load-bearing capacity essential for safe construction in buildings and outdoor surfaces.

Composition features:

- Portland cement for binding strength

- Coarse aggregate (gravel or crushed stone 5-20mm)

- Fine sand for workability and strength

- Water for hydration and chemical reaction

Primary uses include:

- Structural floor slabs in buildings

- Foundation systems and basement floors

- Driveways, patios, and outdoor surfaces

- Industrial flooring for heavy equipment

- Garage floors and workshop surfaces

Core characteristics:

- Compressive strength: 20-40+ MPa depending on mix design

- Thickness: Minimum 100mm for structural applications

- Durability: Designed for decades of heavy use

- Load-bearing capacity: Supports building loads and equipment

Standard concrete requires 24-48 hours of initial setting time and continues gaining strength for up to 28 days during the curing process.

7 Key Differences Between Screed and Concrete Floor

Understanding the fundamental differences between screed and concrete helps you make informed decisions for your specific project requirements. These materials serve distinct purposes despite both containing cement as a primary component.

1. Composition & Aggregate Size

Screed uses fine sand aggregate (0-4mm), creating smooth, dense surfaces ideal for floor coverings. Standard concrete contains coarse aggregate (5-20mm), providing superior strength but a rougher surface texture.

The finer aggregate in screed allows for better surface finishes and easier troweling to achieve ultra-smooth results. Concrete’s coarser aggregate creates a stronger matrix but requires additional finishing layers for most indoor applications.

2. Typical Thickness

Screed applications range from 25-50mm thickness depending on the specific requirements and substrate conditions. Standard concrete floors require a minimum 100mm thickness for structural integrity and load distribution.

Thickness considerations:

- Screed: 25mm minimum bonded, 50mm unbonded/floating

- Concrete: 100mm residential, 150-200mm commercial/industrial

- Application impact: Thicker materials provide greater strength

- Cost implications: Thickness directly affects material quantities

3. Strength and Load-Bearing Capacity

Standard concrete delivers 20-40+ MPa compressive strength suitable for structural applications and heavy load support. Screed typically achieves 15-25 MPa strength, sufficient for surface finishing but not structural support.

Concrete’s superior strength makes it essential for foundations, floor slabs, and areas requiring heavy equipment support. Screed’s lower strength limits its use to finishing applications over structural substrates.

4. Application Method and Setting Time

Concrete requires careful placement, vibration for air removal, and extended curing periods up to 28 days for full strength development. Screed applies quickly with hand or machine smoothing and achieves working strength within 4-6 hours.

Process differences:

- Concrete: Poured, vibrated, screeded, floated, cured

- Screed: Mixed, placed, smoothed, surface finished

- Timeline: Concrete needs days, screed needs hours

- Equipment: Concrete requires heavy machinery, and screed uses hand tools

5. Main Uses

Concrete serves as the structural foundation for buildings, driveways, patios, and heavy-duty industrial applications. Screed provides smooth finishing surfaces for tiles, vinyl, laminate, wooden flooring, and underfloor heating systems.

Understanding each material’s primary purpose helps determine which option suits your specific project requirements and performance expectations.

6. Finish and Surface Quality

Screed produces ultra-smooth, level surfaces perfect for direct application of floor coverings without additional preparation. Standard concrete creates textured, somewhat rough surfaces requiring finishing layers for most indoor applications.

The smooth finish quality of screed eliminates the need for extensive surface preparation before installing tiles, vinyl, or wooden flooring materials.

7. Cost and Maintenance

Screed typically costs more per square meter due to specialised materials and application requirements. Standard concrete offers lower material costs but may require additional finishing layers for specific applications.

Cost comparison factors:

- Material cost: Screed is higher per m², and concrete has a lower volume cost

- Labour requirements: Screed needs skilled application, concrete standard placement

- Long-term maintenance: Both require appropriate surface protection

- Repair considerations: Screed easier surface repairs, concrete structural repairs

Quick Comparison Table Between Concrete Screed and Standard Concrete Floor

Property | Concrete Screed | Standard Concrete Floor |

Aggregate | Fine sand | Coarse stone/gravel |

Thickness | 25–50mm | ≥100mm |

Strength | ~15–25 MPa | 20–40+ MPa |

Setting Time | 4–6 hours | 24–48 hours |

Main Use | Finishing/overlays | Structural base/slabs |

Surface | Smooth | Coarse/rough |

Cost | Higher (per m²) | Lower (per m²) |

When to Use Concrete Screed Instead of Concrete?

Screed becomes the preferred choice when your project demands ultra-smooth surfaces and precision finishing for modern floor coverings. The material’s fine composition and quick-setting properties make it ideal for specific applications where standard concrete falls short.

Perfect Surface Applications

Choose concrete screed for projects requiring perfectly smooth surfaces for floor coverings like tiles, vinyl, laminate, or wooden flooring. Screed provides the ideal substrate for these materials without additional surface preparation.

Primary applications include:

- Tile and stone flooring installations require level substrates

- Luxury vinyl tile (LVT) and laminate flooring preparation

- Wooden floor installation over existing concrete slabs

- Surface levelling and minor repair work

Underfloor Heating Systems

Floating screed systems excel for underfloor heating installations, providing excellent thermal conductivity while protecting heating elements. The material’s thermal properties ensure efficient heat distribution throughout the floor surface, making it the preferred choice for modern heating systems.

Screed’s ability to encapsulate heating pipes or electric elements provides both protection and optimal thermal performance that standard concrete cannot match.

Quick Renovation Projects

Screed’s quick setting time makes it ideal for renovation work where minimal downtime is crucial. The material achieves walking strength within hours rather than the days required for concrete curing, allowing faster project completion and reduced disruption.

When to Use a Standard Concrete Floor Instead of Screed?

Standard concrete becomes essential when structural integrity and load-bearing capacity take priority over surface smoothness. This robust material handles demanding applications that would overwhelm screed’s capabilities.

Structural and Heavy-Duty Applications

Standard concrete floor suits foundation work, structural slabs, and heavy-duty applications requiring superior load-bearing capacity. Choose concrete for exterior surfaces, industrial facilities, and areas supporting heavy equipment or vehicles.

Essential applications include:

- Foundation systems and basement floors requiring structural support

- Structural floor slabs in multi-story buildings

- Driveways, garage floors, and parking areas

- Industrial facilities and warehouse flooring

- Areas requiring heavy machinery or vehicle support

Load-Bearing Requirements

Standard concrete’s superior compressive strength handles building loads, heavy equipment, and vehicle traffic that would damage screed surfaces. The material’s structural integrity provides long-term stability for demanding applications where safety and durability are paramount.

Exterior Durability

Concrete withstands weather exposure, freeze-thaw cycles, and environmental stresses that make it ideal for outdoor applications where screed would fail prematurely. The material’s resistance to temperature variations and moisture makes it the only viable option for exterior flooring.

Common Installation Mistakes with Screed and Concrete Floors

Proper installation techniques determine the long-term success of both screed and concrete floor systems. Understanding common mistakes helps prevent costly failures and ensures optimal performance throughout the floor’s service life.

Surface Preparation Errors

Proper substrate preparation determines bond strength and long-term performance for both screed and concrete applications. Clean, sound substrates prevent delamination and ensure adequate adhesion between layers.

Critical preparation steps:

- Remove all dirt, debris, oil, and loose materials

- Repair cracks and holes in existing substrates

- Apply appropriate primers for bonded screed applications

- Ensure substrate moisture content meets specifications

Poor surface preparation causes bond failures, cracking, and premature floor covering damage that requires costly repairs and replacement.

Incorrect Mixing Ratios

Accurate water-to-cement ratios ensure proper strength development and durability for both materials. Excess water weakens the final product while insufficient water prevents proper hydration and workability.

Common mixing errors include:

- Adding excessive water for easier placement

- Inadequate mixing time results in material segregation

- Wrong aggregate proportions affecting strength

- Improper additive dosing for specialised applications

Professional concrete mixing equipment and experienced operators prevent these costly mistakes that compromise long-term performance.

Ignoring Moisture Content

Excessive substrate moisture causes bonding failures and floor covering damage in both screed and concrete applications. Moisture testing and appropriate drying time prevent these expensive problems.

Moisture-related issues:

- Substrate moisture exceeding material specifications

- Inadequate drying time before floor covering installation

- Missing moisture barriers in ground-contact applications

- Condensation problems in climate-controlled environments

Proper moisture management protects your investment and ensures warranty compliance for floor covering materials.

Rushing, Curing, and Drying

Adequate curing time allows materials to achieve design strength and prevents premature loading that causes cracking and structural problems. Both screed and concrete require appropriate time for strength development.

Curing best practices:

- Follow manufacturer specifications for curing time

- Maintain appropriate temperature and humidity conditions

- Protect surfaces from rapid moisture loss

- Avoid heavy traffic until adequate strength development

Maintenance Tips for Long-Lasting Concrete and Screed Floors

Proactive maintenance keeps concrete and screed floors looking good and performing well for decades. Using the right cleaning products and protective measures significantly extends their service life.

Routine Cleaning Recommendations

- Use pH-neutral cleaners appropriate for the surface type

- Avoid harsh chemicals that damage surface integrity

- Regular sweeping and mopping prevent abrasive buildup

- Address spills immediately to prevent staining

Protection Strategies

- Apply appropriate sealers for surface protection

- Use mats and protective coverings in high-traffic areas

- Control moisture levels to prevent damage

- Regular inspection for early problem detection

Professional Maintenance Scheduling

Schedule annual inspections to identify potential problems before they require expensive repairs. Professional assessment catches issues like cracking, delamination, or wear patterns early.

Sealing

Properly sealed surfaces resist staining, moisture penetration, and chemical damage while maintaining an attractive appearance longer than untreated surfaces.

Bottom Line

Making the right choice between concrete screed and standard concrete floor impacts every aspect of your project, from initial cost to long-term performance. Choose screed when you need ultra-smooth surfaces for tiles, vinyl, laminate, wooden flooring, or underfloor heating systems over existing structural slabs. Choose concrete for foundations, structural floors, driveways, industrial applications, and any situation requiring superior load-bearing capacity.

Every construction professional knows the frustration of dealing with subpar concrete that cracks, fails, or doesn’t meet specifications. At Pro-Mix Concrete, we’ve eliminated those headaches by perfecting our mixing processes and maintaining the highest quality standards in the industry.

We’ve become the go-to choice for contractors who refuse to compromise because we understand what’s really at stake. Your clients expect perfection, your timelines demand reliability, and your budget requires value. Pro-Mix Concrete delivers all three through decades of experience, advanced facilities, and a strong commitment to your success.

Call us: 020 7458 4747 today for a free consultation on your next project. Let’s discuss how our premium materials and expert guidance can deliver the results you need.

Frequently Asked Questions

What is the difference between concrete screed and a standard concrete floor?

Concrete screed is a thin finishing layer (25-50mm) made with fine sand aggregate for smooth surfaces under floor coverings. Standard concrete floors are thick structural bases (100mm+) with coarse aggregate providing load-bearing strength for foundations and heavy-duty applications.

When should I use screed instead of concrete for a flooring project?

Use screed when you need perfectly smooth surfaces for tiles, vinyl, laminate, or wooden flooring over existing concrete slabs. Also choose screed for underfloor heating installations, quick renovation projects, and situations requiring fast turnaround times with minimal curing delays.

What are common mistakes during screed installation, and how can they be avoided?

Common mistakes include poor surface preparation, incorrect water ratios, ignoring substrate moisture content, and rushing curing time. Avoid these by thoroughly cleaning substrates, following manufacturer mixing specifications, testing moisture levels, and allowing proper curing time before loading.

How do you maintain and care for concrete and screed floors over time?

Maintain floors through regular cleaning with pH-neutral products, immediate spill cleanup, appropriate sealing every few years, and annual professional inspections. Protect high-traffic areas with mats, control moisture levels, and address minor issues promptly to prevent major repairs.

- Dennis Broderick

- Dennis Broderick is the founder and owner of Pro-Mix Concrete Company, a trusted name in ready-mix concrete solutions across the UK. With over 20 years of hands-on experience in the construction and concrete industry, Dennis brings unmatched expertise, practical insights, and a commitment to quality on every project - from residential driveways to large-scale commercial developments.

BlogJanuary 19, 2026Different Types of Curing Methods in Concrete Construction

BlogJanuary 19, 2026Different Types of Curing Methods in Concrete Construction BlogJanuary 16, 2026What is the Best Mix for Concrete UK?

BlogJanuary 16, 2026What is the Best Mix for Concrete UK? BlogJanuary 15, 2026Concrete Pumping vs Wheelbarrowing: Which Method is Right for Your Pour?

BlogJanuary 15, 2026Concrete Pumping vs Wheelbarrowing: Which Method is Right for Your Pour? BlogJanuary 13, 2026How Do Concrete Boom Pumps Work?

BlogJanuary 13, 2026How Do Concrete Boom Pumps Work?