Concrete is a versatile and durable material that is used in a wide range of construction projects, from building foundations to bridges and highways. However, to ensure the quality and performance of concrete, it is important to use the correct mixing ratio. In this article, we will explore the factors that affect concrete mixing ratios, standard mixing ratios for different types of concrete, tools, and techniques for mixing concrete, and testing and curing concrete.

Concrete Mixing Ratios: What You Need to Know

By reading this article, you will learn:

– The factors that affect concrete mixing ratios, including the type of cement, water-cement ratio, type and size of aggregates, and admixtures.

– Standard mixing ratios for plain concrete, reinforced concrete, lightweight concrete, high-strength concrete, and self-compacting concrete.

– Tools and techniques for mixing concrete, common mistakes to avoid, and testing and curing methods for fresh and hardened concrete.

Factors that affect concrete mixing ratio

The quality and performance of concrete are affected by several factors, including the type of cement, water-cement ratio, type and size of aggregates, and admixtures. Let’s take a closer look at each of these factors:

A. Type of cement

Different types of cement have different properties and strengths, which can affect the mixing ratio. For example, Portland cement is the most commonly used type of cement and is suitable for most construction projects. However, if you need a faster setting time, you may opt for rapid-hardening cement. On the other hand, if you need a longer setting time, you may use low-heat cement.

B. Water-cement ratio

The water-cement ratio is the ratio of the weight of water to the weight of cement used in the mix. This ratio is critical to the strength and durability of the concrete. If the ratio is too high, the concrete will be weak and prone to cracking and shrinkage. If the ratio is too low, the concrete will be difficult to work with and may not set properly.

C. Type and size of aggregates

Aggregates are the materials that are added to the cement and water to give the concrete its strength and durability. The type and size of aggregates used in the mix can affect the mixing ratio. For example, if you use large, heavy aggregates, you may need more cement and water to achieve the desired consistency.

D. Admixtures

Admixtures are chemicals that are added to the concrete mix to improve its properties, such as workability, strength, and durability. Some common admixtures include air-entraining agents, which improve the freeze-thaw resistance of the concrete, and superplasticizers, which improve the workability of the concrete.

E. Impact of each factor on the quality and performance of concrete

Each of these factors can affect the quality and performance of the concrete in different ways. For example, using too much water can weaken the concrete and make it more prone to cracking, while using too little water can make the concrete difficult to work with and may cause it to set too quickly. Understanding how each factor affects the mixing ratio is essential to ensuring the quality and performance of the concrete.

Standard concrete mixing ratios

Now that we have an understanding of the factors that affect concrete mixing ratios, let’s look at some standard mixing ratios for different types of concrete.

A. Plain concrete

Plain concrete is the most basic type of concrete and is used in a variety of applications, such as sidewalks, driveways, and patios.

1. Definition and uses

Plain concrete is a mixture of cement, water, and aggregates, with no additional reinforcement.

2. Mixing ratio and proportions

The standard mixing ratio for plain concrete is 1:2:3, which means one part cement, two parts sand, and three parts gravel or crushed stone.

B. Reinforced concrete

Reinforced concrete is used in applications where additional strength and durability are required, such as building foundations, bridges, and highways.

1. Definition and uses

Reinforced concrete is a mixture of cement, water, and aggregates, with the addition of steel reinforcement to provide additional strength and durability.

2. Mixing ratio and proportions

The standard mixing ratio for reinforced concrete is 1:2:3:0.4, which means one part cement, two parts sand, three parts gravel or crushed stone, and 0.4 parts steel reinforcement.

3. Steel reinforcement and its impact on the mixing ratio

The amount of steel reinforcement used in the mix can affect the mixing ratio. If more steel reinforcement is required, the amount of cement and aggregates may need to be adjusted to maintain the desired strength and consistency.

C. Lightweight concrete

Lightweight concrete is used in applications where weight is a concern, such as in precast concrete panels and roof decks.

1. Definition and uses

Lightweight concrete is a mixture of cement, water, and lightweight aggregates, such as expanded shale, clay, or perlite.

2. Mixing ratio and proportions

The standard mixing ratio for lightweight concrete is 1:2:4, which means one part cement, two parts sand, and four parts lightweight aggregates.

3. Types of lightweight aggregates

There are several types of lightweight aggregates that can be used in the mix, each with its own properties and strengths. The choice of aggregate will depend on the specific application and requirements of the project.

D. High-strength concrete

High-strength concrete is used in applications where the concrete needs to withstand high loads and stresses, such as in high-rise buildings and bridges.

1. Definition and uses

High-strength concrete is a mixture of cement, water, and aggregates, with the addition of special cements and aggregates that provide additional strength and durability.

2. Mixing ratio and proportions

The standard mixing ratio for high-strength concrete is 1:1.5:2, which means one part cement, 1.5 parts sand, and two parts gravel or crushed stone.

3. Special cement and aggregates used for high-strength concrete

Special cements and aggregates, such as silica fume and steel fibers, are often used in high-strength concrete to provide additional strength and durability.

E. Self-compacting concrete

Self-compacting concrete is used in applications where it is difficult or impossible to use traditional concrete placement methods, such as in complex shapes and structures.

1. Definition and uses

Self-compacting concrete is a mixture of cement, water, and aggregates, with the addition of special admixtures that allow the concrete to flow and compact itself.

2. Mixing ratio and proportions

The standard mixing ratio for self-compacting concrete is 1:1.2:2, which means one part cement, 1.2 parts sand, and two parts gravel or crushed stone.

3. Characteristics and benefits of self-compacting concrete

Self-compacting concrete has several characteristics and benefits, such as improved workability and reduced labor costs.

Tools and techniques for mixing concrete

Now that we have an understanding of the standard mixing ratios for different types of concrete, let’s look at some tools and techniques for mixing concrete.

A. Basic equipment and materials needed

The basic equipment and materials needed for mixing concrete include a concrete mixer, cement, sand, gravel or crushed stone, and water.

B. Safety precautions

When mixing concrete, it is important to take appropriate safety precautions, such as wearing protective clothing and eyewear, and ensuring that the mixing area is well-ventilated.

C. Steps for preparing and mixing concrete

The steps for preparing and mixing concrete include measuring and preparing the materials, adding the materials to the mixer in the correct order, and mixing the materials for the appropriate amount of time.

D. Common mistakes in mixing concrete and how to avoid them

Common mistakes in mixing concrete include using too much or too little water, not mixing the materials for the appropriate amount of time, and not measuring the materials correctly. To avoid these mistakes, it is important to follow the standard mixing ratios and instructions carefully.

Testing and curing concrete

Testing and curing concrete is essential to ensuring its quality and performance. Let’s take a closer look at the importance of testing and curing concrete, as well as some common tests and curing methods.

A. Importance of testing and curing concrete

Testing and curing concrete is important to ensure that it meets the required strength and durability standards, and to prevent cracking and other forms of damage.

B. Tests for fresh concrete

Tests for fresh concrete include the slump test, flow test, and air meter test, which measure the workability and consistency of the concrete.

1. Slump test

The slump test measures the consistency of the concrete by measuring the amount of settlement that occurs when a cone-shaped mold is filled and then removed.

2. Flow test

The flow test measures the flow rate of the concrete by measuring the time it takes for a certain amount of concrete to flow through a funnel.

3. Air meter test

The air meter test measures the amount of air that is entrained in the concrete, which is important for freeze-thaw resistance.

C. Tests for hardened concrete

Tests for hardened concrete include the compressive strength test, flexural strength test, and durability tests, which measure the strength and durability of the concrete over time.

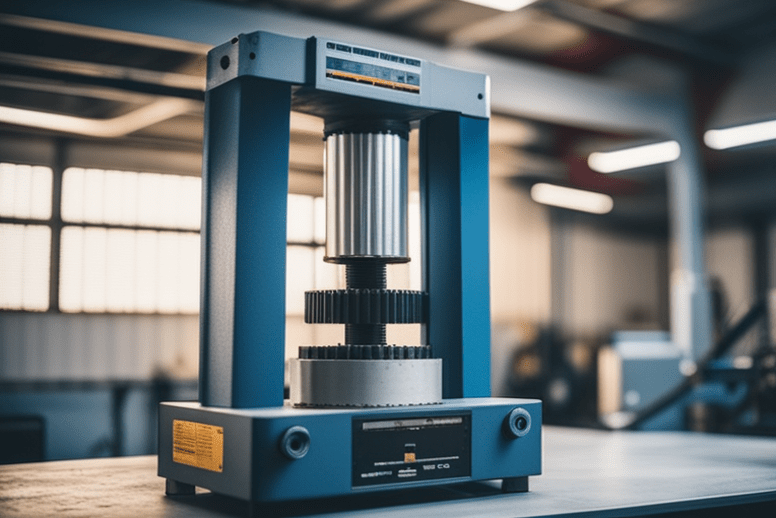

1. Compressive strength test

The compressive strength test measures the maximum load that the concrete can withstand before it fails.

2. Flexural strength test

The flexural strength test measures the maximum load that the concrete can withstand before it cracks.

3. Durability tests

Durability tests measure the resistance of the concrete to environmental factors such as freeze-thaw cycles and chemical exposure.

D. Methods of curing concrete

Methods of curing concrete include wet curing, membrane curing, and curing compounds, which help the concrete to retain moisture and gain strength.

1. Wet curing

Wet curing involves keeping the concrete moist for a period of time after it has been poured, which helps to prevent cracking and improve the strength and durability of the concrete.

2. Membrane curing

Membrane curing involves covering the concrete with a waterproof membrane, which helps to retain moisture and improve the strength and durability of the concrete.

3. Curing compounds

Curing compounds are chemicals that are applied to the surface of the concrete to help it retain moisture and gain strength.

Personal experience: Importance of using the Correct Mixing Ratio

Concrete mixing ratios are a vital aspect of any construction project. As a civil engineer with over a decade of experience, I have seen firsthand the consequences of not using the correct mixing ratio. One particular project comes to mind where the contractor used a higher water-cement ratio than the recommended amount. As a result, the concrete had a low compressive strength and poor durability. The structure had to be demolished, and the client incurred significant additional costs.

On another project, the contractor used the wrong type of cement for a high-strength concrete mix, resulting in a low compressive strength. The project had to be delayed, and additional resources were needed to rectify the issue.

These experiences highlight the importance of using the correct mixing ratio for each type of concrete. It not only affects the quality and durability of the structure but also the safety of those who will use it. As professionals, we must ensure that the correct ratios are used and educate our colleagues and clients on the importance of this aspect of concrete construction.

Conclusion

In conclusion, the correct mixing ratio is essential to the quality and performance of concrete. Understanding the factors that affect the mixing ratio, standard mixing ratios for different types of concrete, tools and techniques for mixing concrete, and testing and curing concrete are all important for ensuring the success of your construction project. By following these guidelines and best practices, you can ensure that your concrete is strong, durable, and long-lasting.

If you want to learn more about concrete mixing ratios and other construction-related topics, be sure to check out additional resources of Ready Mix Concrete London and further reading recommendations.

Frequently Asked Questions

Q. What is the ideal water-cement ratio for concrete mixing?

A. The ideal water-cement ratio for concrete mixing is 0.50.

Q. How much sand should I use in a concrete mix?

A. A concrete mix requires approximately 2-3 times as much sand as cement.

Q. What is the strength of a concrete mix with a 1:2:3 ratio?

A. A concrete mix with a 1:2:3 ratio has a compressive strength of 2,500 psi.

Q. How do I adjust the concrete mix ratio for hot weather?

A. In hot weather, increase the amount of water and decrease the cement in the mix.

Q. Who determines the concrete mixing ratio on a construction site?

A. The engineer or contractor on the construction site determines the concrete mixing ratio.

Q. What if I don’t have the exact materials for the mix ratio?

A. Adjust the ratios proportionally and test the resulting mix for strength before use.